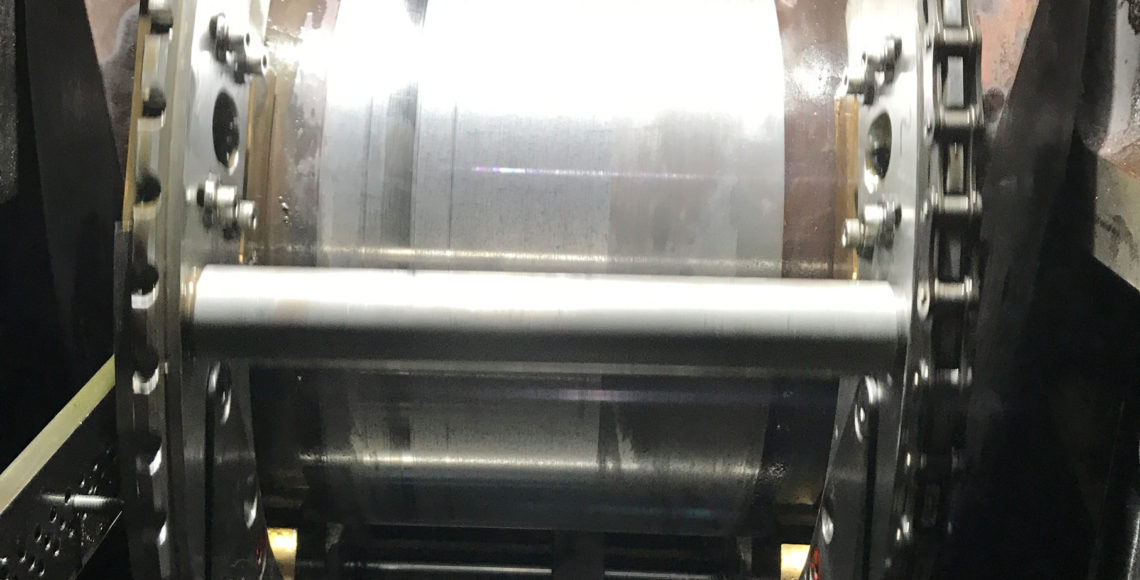

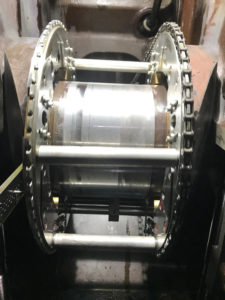

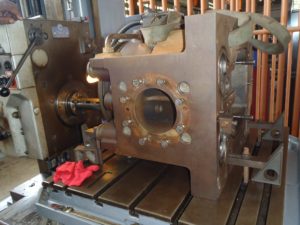

Man Crankpin Failure Being Machined And Polished To The Nearest Undersize Insitu

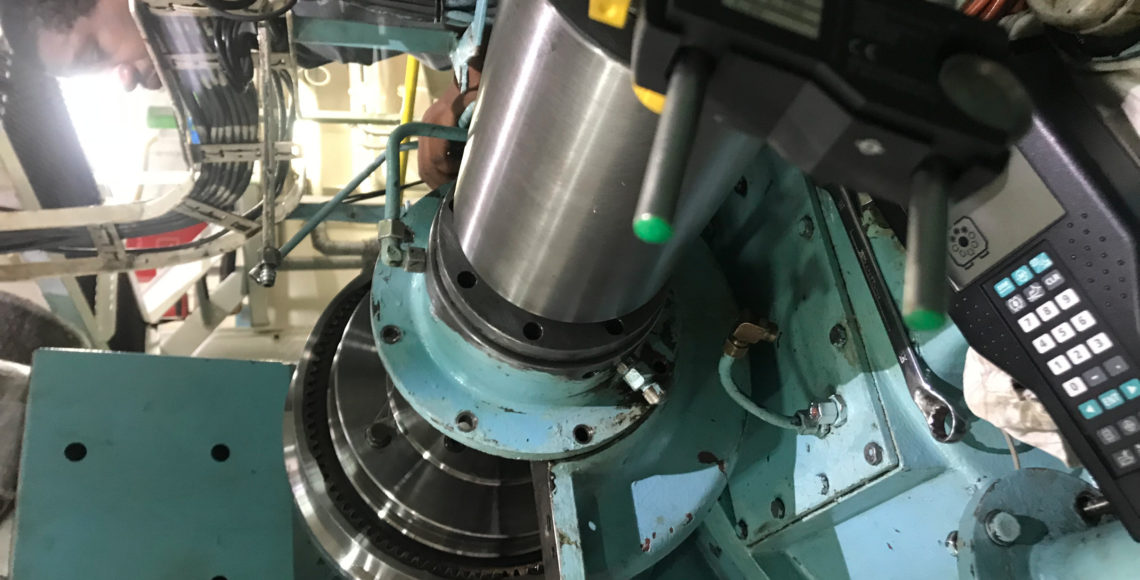

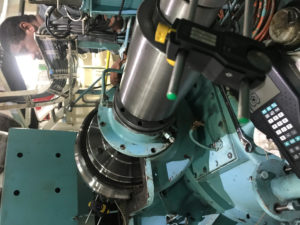

MAK Main Engine PTO alignment and chockfast to Speed upGearbox and Shaft Generator

D&D Engineering in joint venture with worlds’ most reliable and professional crankshaft machining company

- Crankpin Radii Being Machined Using Water Level Indicator

- Crankpin Radii Being Machined Using Water Level Indicator

- Crankpin Radii Being Machined Using Water Level Indicator

- Crankpin Radii Being Machined Using Water Level Indicator

- Crankpin Radii Being Machined Using Water Level Indicator

Crankpin radii being machined using water level indicator for precise and concentric radii and crankpin centerlin

Inspections – With a detailed report of the condition and recommendations for repairs

Annealing process – The capabilities of reducing the hardness of crankpin journals to acceptable limits

Damaged or destroyed Radii – We will restore its original centreline and ensure its concentricity with the crankpin

Machining crankpin to acceptable undersize – The capability of machining and polishing to manufacturers specs the damaged crankpin

Bearing supply for damaged journals – we will supply recommended undersize bearings from the worlds leading bearing manufacturers. All repairs are class certified and completed within budget and within a reasonable time to avoid unnecessary downtime.

Port Authority of Trinidad & Tobago – Ship To Shore Crane Rails Replacement

Port Authority of Trinidad & Tobago – Ship To Shore Crane Rails Replacement

Complete installation of crane rails on ship to shore crane

Ship to shore container crane

Ship to shore replacement crane rails

Cylinder Head Components Service & Installation

Overhaul Report

Vessel Name: Atlantic Provider

Engine Type: 12V 32/40

Location: Port-of-Spain, Trinidad & Tobago.

The following jobs were carried out:

- Crankshaft deflection measurements

- Bearing and crankshaft inspection

- Cylinder head components inspection

- Fuel pump inspection

- Fuel injection valve inspection

- Liner inspection

- Piston inspection

- Valve assembly inspection

- Liner casing inspection

- Connecting rod bush inspection

- Turbocharger inspection

Cylinder head

Cylinder head dismantled at the workshop and inspected.

- Valve guide measurement taken (not acceptable) – new guides installed.

- Valve rotator inspected. (All exhaust valve rotators renewed)

- Exhaust valves and inlet valves inspected. (Unacceptable)

- Inlet and exhaust valves replaced.

- Turbochargers inspected. (Unacceptable) – both Turbochargers replaced.

- Inlet and exhaust valve seats inspected (Unacceptable) – All valve seats were replaced.

- Cylinder numbers A1, A2, A4, A5, B3, B4, B5, B6 (Oversized exhaust valve seats of 2mm were fitted)

- Starting valves serviced, all seals replaced, pilot valve seals renewed and valves tested.

- Cylinder head fire rings replaced on all 12 cylinders.

- Cylinder head sealing gasket replaced.

All mechanical works carried out by D&D Engineering Services.

- Cylinder Head Components Service & Installation

- Cylinder Head Components Service & Installation

- Cylinder Head Components Service & Installation

- Cylinder Head Components Service & Installation

- Cylinder Head Components Service & Installation

Piston – Pin and Liner Service & Installation

Overhaul Report

Vessel Name: Atlantic Provider

Engine Type: 12V 32/40

Location: Port-of-Spain, Trinidad & Tobago.

The following jobs were carried out:

- Crankshaft deflection measurements

- Bearing and crankshaft inspection

- Cylinder head components inspection

- Fuel pump inspection

- Fuel injection valve inspection

- Liner inspection

- Piston inspection

- Valve assembly inspection

- Liner casing inspection

- Connecting rod bush inspection

- Turbocharger inspection

Liner

All liner dismounted and cleaned. All honed according to MAN instruction. After honing all liner measurement taken and B1-B2 unit dimension found out of limit. Mentioned liner strongly recommended replacing. (Measurements attached) . Recommended at next overhaul all liners be replaced.

Pistons

All pistons dismounted and cleaned. Groove measurement taken and it was found that B1, B3, B5 1st groove and A2, A3, A4, A5, A6 2nd groove measurement out of limits. All pistons to be replaced at next overhaul.

- Piston pin measured and found OK.

- Piston skirt inspected and found OK.

- All piston pin bearings renewed.

- Piston retaining bolts renewed

All mechanical works carried out by D&D Engineering Services.

- Piston – Pin and Liner Service & Installation

- Piston – Pin and Liner Service & Installation

- Piston – Pin and Liner Service & Installation

- Piston – Pin and Liner Service & Installation

- Piston – Pin and Liner Service & Installation

- Piston – Pin and Liner Service & Installation

Turbocharger Service, Overhaul & Assembly

Overhaul Report

Vessel Name: Atlantic Provider

Engine Type: 12V 32/40

Location: Port-of-Spain, Trinidad & Tobago.

The following jobs were carried out:

- Crankshaft deflection measurements

- Bearing and crankshaft inspection

- Cylinder head components inspection

- Fuel pump inspection

- Fuel injection valve inspection

- Liner inspection

- Piston inspection

- Valve assembly inspection

- Liner casing inspection

- Connecting rod bush inspection

- Turbocharger inspection

- Turbocharge Service, Overhaul & Assembly

- Turbocharge Service, Overhaul & Assembly

- Turbocharge Service, Overhaul & Assembly

- Turbocharge Service, Overhaul & Assembly

- Turbocharge Service, Overhaul & Assembly

Crankpin Bearing Inspection & Installation

Overhaul Report

Vessel Name: Atlantic Provider

Engine Type: 12V 32/40

Location: Port-of-Spain, Trinidad & Tobago.

The following jobs were carried out:

- Crankshaft deflection measurements

- Bearing and crankshaft inspection

- Cylinder head components inspection

- Fuel pump inspection

- Fuel injection valve inspection

- Liner inspection

- Piston inspection

- Valve assembly inspection

- Liner casing inspection

- Connecting rod bush inspection

- Turbocharger inspection

Bearing and crankshaft

- Connecting rod bearing inspected and all 12 pairs renewed.

- Crank pin inspection completed and polished.

- #3.#5.# 7 main bearing inspection carried out. Bearing condition acceptable.

- No scratches, no visual marks, clearances & tolerances between acceptable limits.

- Thrust pad inspected. Acceptable.

All mechanical works carried out by D&D Engineering Services.

- Specialist workforce providing first class ship repairs solutions in Trinidad & Tobago. We are available 24/7 within the caribbean and internationally. Ship Repair, Ship Repair Trinidad, D&D Engineering Services Ltd

- Specialist workforce providing first class ship repairs solutions in Trinidad & Tobago. We are available 24/7 within the caribbean and internationally. Ship Repair, Ship Repair Trinidad, D&D Engineering Services Ltd

- Specialist workforce providing first class ship repairs solutions in Trinidad & Tobago. We are available 24/7 within the caribbean and internationally. Ship Repair, Ship Repair Trinidad, D&D Engineering Services Ltd

- Crankpin Bearing Inspection & Installation

- Crankpin Bearing Inspection & Installation

- Crankpin Bearing Inspection & Installation

Piston Crown & Skirt Assembly

Overhaul Report

Vessel Name: Atlantic Provider

Engine Type: 12V 32/40

Location: Port-of-Spain, Trinidad & Tobago.

The following jobs were carried out:

- Crankshaft deflection measurements

- Bearing and crankshaft inspection

- Cylinder head components inspection

- Fuel pump inspection

- Fuel injection valve inspection

- Liner inspection

- Piston inspection

- Valve assembly inspection

- Liner casing inspection

- Connecting rod bush inspection

- Turbocharger inspection

Pistons

All pistons dismounted and cleaned. Groove measurement taken and it was found that B1, B3, B5 1st groove and A2, A3, A4, A5, A6 2nd groove measurement out of limits. All pistons to be replaced at next overhaul.

- Piston pin measured and found OK.

- Piston skirt inspected and found OK.

- All piston pin bearings renewed.

- Piston retaining bolts renewed

All mechanical works carried out by D&D Engineering Services.

- Specialist workforce providing first class ship repairs solutions in Trinidad & Tobago. We are available 24/7 within the caribbean and internationally. Ship Repair, Ship Repair Trinidad, D&D Engineering Services Ltd

- Specialist workforce providing first class ship repairs solutions in Trinidad & Tobago. We are available 24/7 within the caribbean and internationally. Ship Repair, Ship Repair Trinidad, D&D Engineering Services Ltd

- Specialist workforce providing first class ship repairs solutions in Trinidad & Tobago. We are available 24/7 within the caribbean and internationally. Ship Repair, Ship Repair Trinidad, D&D Engineering Services Ltd

- Specialist workforce providing first class ship repairs solutions in Trinidad & Tobago. We are available 24/7 within the caribbean and internationally. Ship Repair, Ship Repair Trinidad, D&D Engineering Services Ltd

- Specialist workforce providing first class ship repairs solutions in Trinidad & Tobago. We are available 24/7 within the caribbean and internationally. Ship Repair, Ship Repair Trinidad, D&D Engineering Services Ltd

- Specialist workforce providing first class ship repairs solutions in Trinidad & Tobago. We are available 24/7 within the caribbean and internationally. Ship Repair, Ship Repair Trinidad, D&D Engineering Services Ltd

Fuel Pump & Injectors Service, Calibration & Assembly

Overhaul Report

Vessel Name: Atlantic Provider

Engine Type: 12V 32/40

Location: Port-of-Spain, Trinidad & Tobago.

The following jobs were carried out:

- Crankshaft deflection measurements

- Bearing and crankshaft inspection

- Cylinder head components inspection

- Fuel pump inspection

- Fuel injection valve inspection

- Liner inspection

- Piston inspection

- Valve assembly inspection

- Liner casing inspection

- Connecting rod bush inspection

- Turbocharger inspection

Fuel pump inspection

Fuel pumps inspected and main plunger barrels renewed. Seals and helical barrels also replaced.

Fuel Injection valves

- All fuel injection valves dismounted and cleaned.

- Fuel valve nozzles renewed.

- Injection block lapped and sealed.

- Injectors calibrated and tested to 600 bars.

All mechanical works carried out by D&D Engineering Services.

- Specialist workforce providing first class ship repairs solutions in Trinidad & Tobago. We are available 24/7 within the caribbean and internationally. Ship Repair, Ship Repair Trinidad, D&D Engineering Services Ltd

- Fuel Pump & Injectors Service, Calibration & Assembly

- Fuel Pump & Injectors Service, Calibration & Assembly

- Fuel Pump & Injectors Service, Calibration & Assembly

- Fuel Pump & Injectors Service, Calibration & Assembly

- Fuel Pump & Injectors Service, Calibration & Assembly

- Fuel Pump & Injectors Service, Calibration & Assembly